Corrosion Analysis Coupons are used to classify the suitability of control rooms and protected environments that house other electronic equipment. Previously only heavy industrial facilities, such as petroleum refineries or paper mills, were subject to computer failures due to corrosion from gaseous contaminants. Today, new materials and manufacturing processes make electronic equipment more susceptible to corrosion failures. The effects of gaseous contaminants can now be felt almost everywhere from urban environments to agricultural areas.

The corrosion coupon has metal Corrosion Classification per ISA 71.04-2013 samples of pure copper and silver and are to be placed in the protected room or contaminated airstream for 30 days to allow contaminants to react with the metals and develop corrosion films. The type and thickness of the corrosion films provide information on the class of contaminant (sulfur, chlorine, or other) and the severity of the contamination.

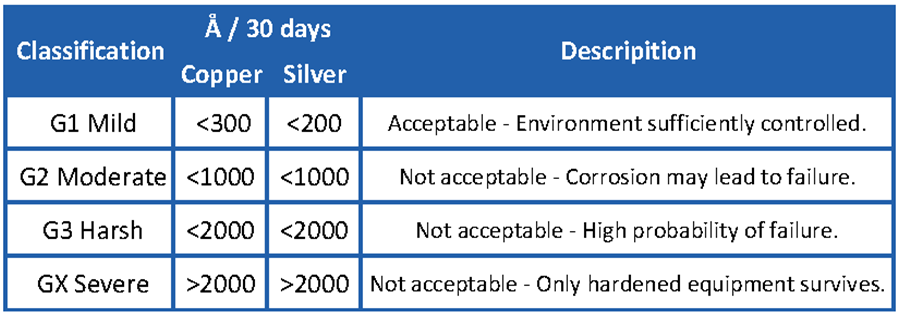

Corrosion Classification per ISA 71.04-2013

Corrosion Analysis Coupons are instrumental in classifying an environment per industry standards for the suitability to house electronics. The most referenced standard is ISA 71.04-2013, Environmental Conditions for Process Measurements and Control Systems: Airborne Contaminants. The coupons are also useful in quantifying corrosion and speciating contaminants that affect rotary equipment such as compressors and turbines.

PHYSICAL PROPERTIES

Corrosion Analysis Coupons (#745-1001) shall have the following physical properties:

Dimensions : 5.25 x 4 inches (150×400 mm)

Copper Purity : ≥99.99%

Silver Purity : ≥99.99%

Accuracy: ± 25Å of total corrosion standardized to 30 days